3D Scanners UK reduce production time of unique horse toys by 50%

Engineers utilise a combination of 3d scanning technology and PolyWorks software to improve efficiency in production process

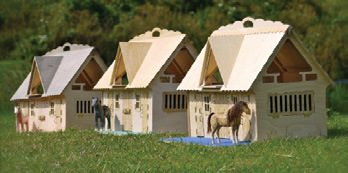

Grovely Wood is a company specialising in unique, durable horse themed toys. Tricia Grady, owner and founder of Grovely Wood, approached 3D Scanners with the hope of finding a means to reducing production time of these toys significantly.

The existing process

Their current process involved Tricia's daughter cutting and sanding the horse profiles from Birch, they were then glued together before being hand sanded again. This process alone took roughly two and a half hours.

The process was then competed by coating the wooden toys in natural Osmo® oil/wax at least twice to produce a beautiful yet hard-wearing toy.

The new and improved process

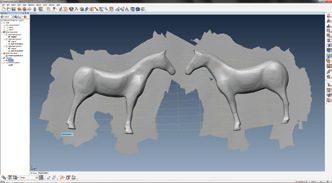

As Tricia had access to a CNC machine with Mach 3 software in her workshop, the obvious solution was to 3d scan the horse profiles producing a polygon mesh, called an stl file. This type of file can be imported directly into the CNC machine and used to produce a machined version.

The profiles would then need to be glued together with minimal fine hand sanding therefore taking a fraction of time in comparison to the initial process.

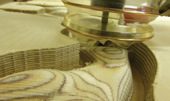

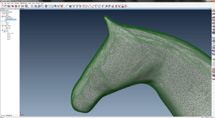

The profiles were scanned at 3D Scanners UK's Coventry premises using the new PolyWorks® 2014 Real Time Meshing™ feature.

This new feature creates a polygon mesh whilst scanning, eliminating the need to align and merge the point clouds into a polygon mesh later on. Consequently, this speeds up the whole process by making it easier to spot any issues at the time of scanning.

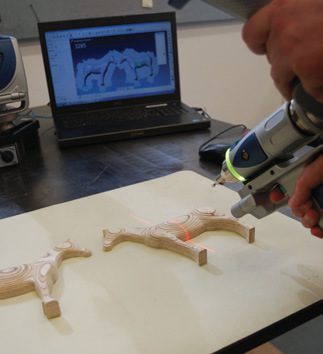

The below photographs demonstrate the polygon mesh appearing whilst the toy horse profile is being scanned.

Using PolyWorks Inspector

A plane is used to crop the unwanted data picked up from the surface it was scanned on. The screenshot below is a close up of the polygon mesh in wireframe mode.

The polygon mesh (stl) was then available to be imported into Mach 3 for use on the CNC machine at Grovely Wood, significantly reducing production time by 50%.

'We would like to thank all the team at 3D Scanners UK for their outstanding assistance and support. Your kind eorts have been really instrumental in reducing a very labour intensive job down to something far more manageable.' and we really do 'THANK YOU ALL'

All our very best regards,

Tricia & Emily Sims