The use of 3D Scanning in the turbine blade industry

3D Scanners UK play pivotal role in speeding up the production process for manufacturing a full turbine blade.

For many years now, turbine blade manufacturers and re-manufacturers have been synonymous with quality manufacture through a full spectrum of applications.

Most turbine applications, from aero-propulsion to power generation, demand extreme reliability and, because of their original equipment cost, high utilisation - often in extremely harsh operating conditions.

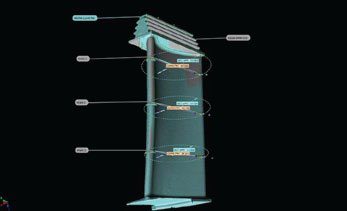

Over the past ten years the blade industry has evolved and, with the explosion of turbine applications within the power and energy markets, 3D scanning technologies have been highly influential. Non-contact equipment is required to collect data and can range from laser scanners to photogrammetry systems. Such technology has the capability to collect from 20,000 points per second to 4,000,000 points per capture, reducing the time required to scan a turbine blade from days to minutes as a result.

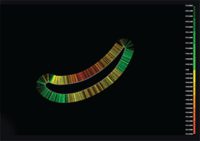

Moreover, when these systems are used in conjunction with the PolyWorks Airfoil Gauge module, blade manufacturers and re-manufacturers have the ability to create blades, adjust them on CAD and scanned parts, fit camber lines, extract all measurements required and visualise and report these measurements, significantly improving efficiency and saving additional time.

The end result is a fully manufactured turbine blade in weeks rather than months. 3D Scanners UK have been instrumental in this time of change for the industry.