3D Scanners scan & inspect a cannon dated 1807 using PolyWorks

The cannons were recovered from a shipwreck near Dover by David Knight who operates his boat out of Dover for commercial diving and survey support. David is also a keen amateur marine archaeologist. As part of his work he is preparing a paper on the cannon and the advantages of 3D scanning.

The Aim

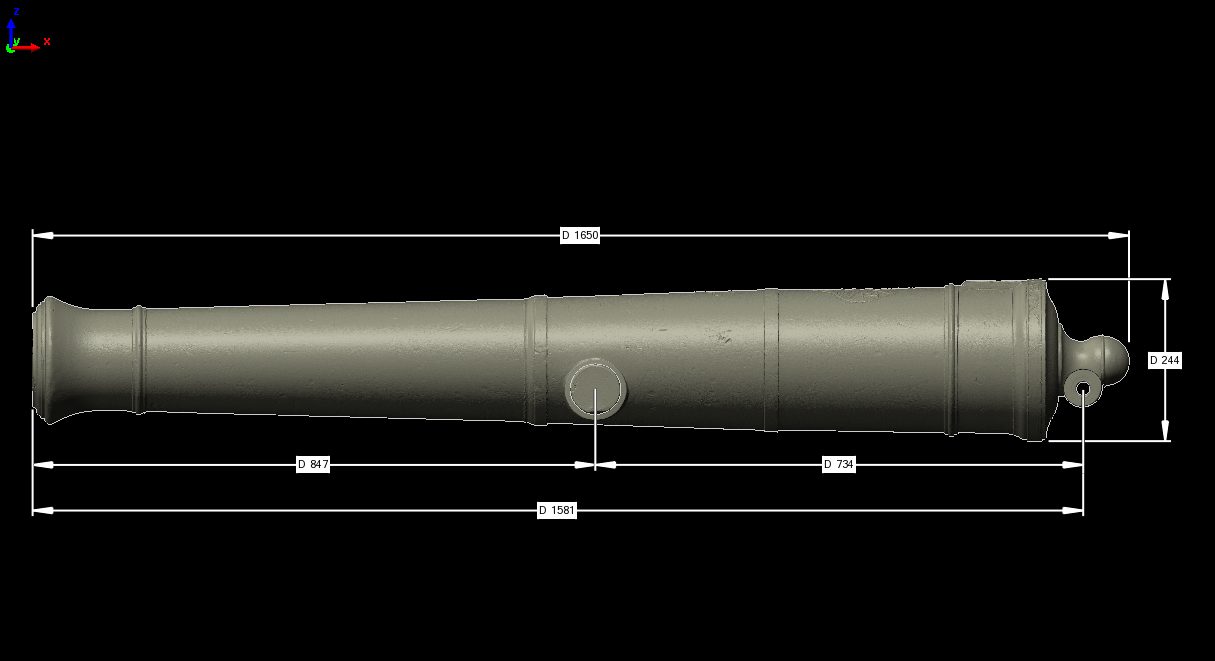

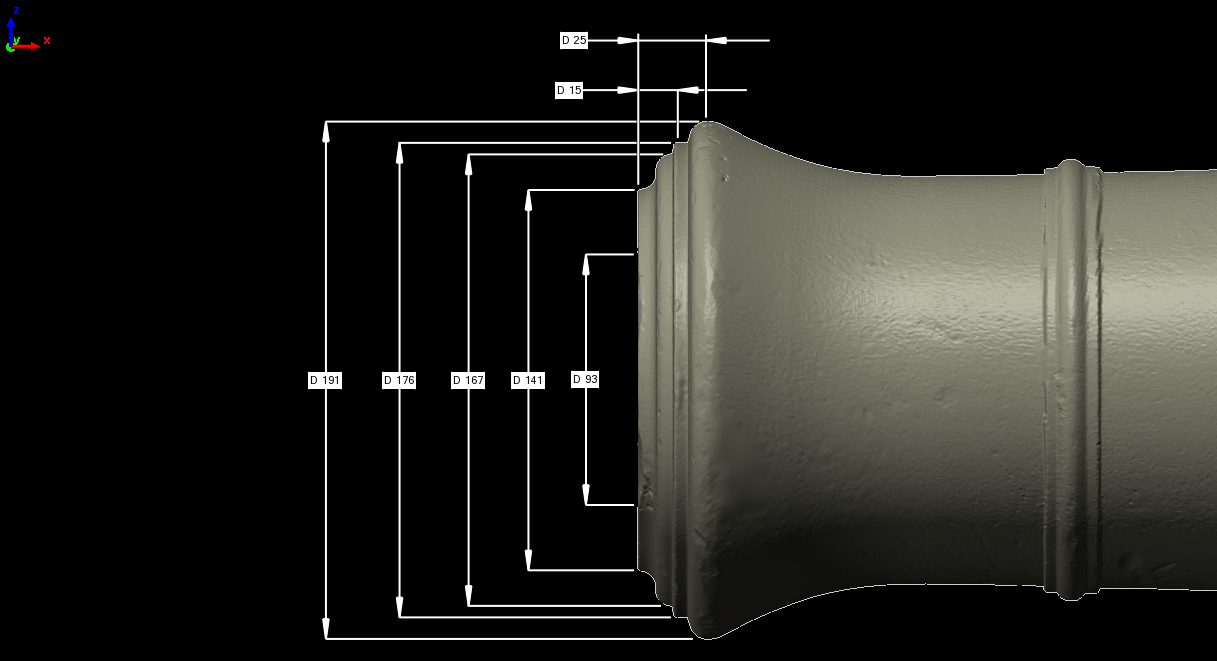

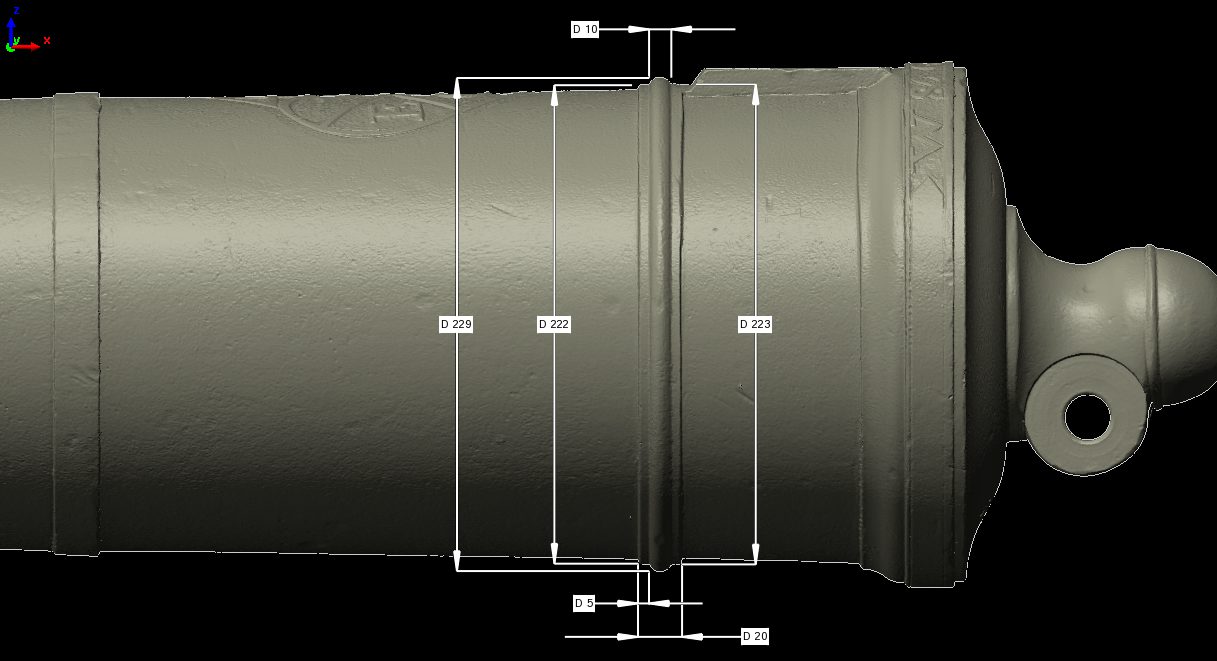

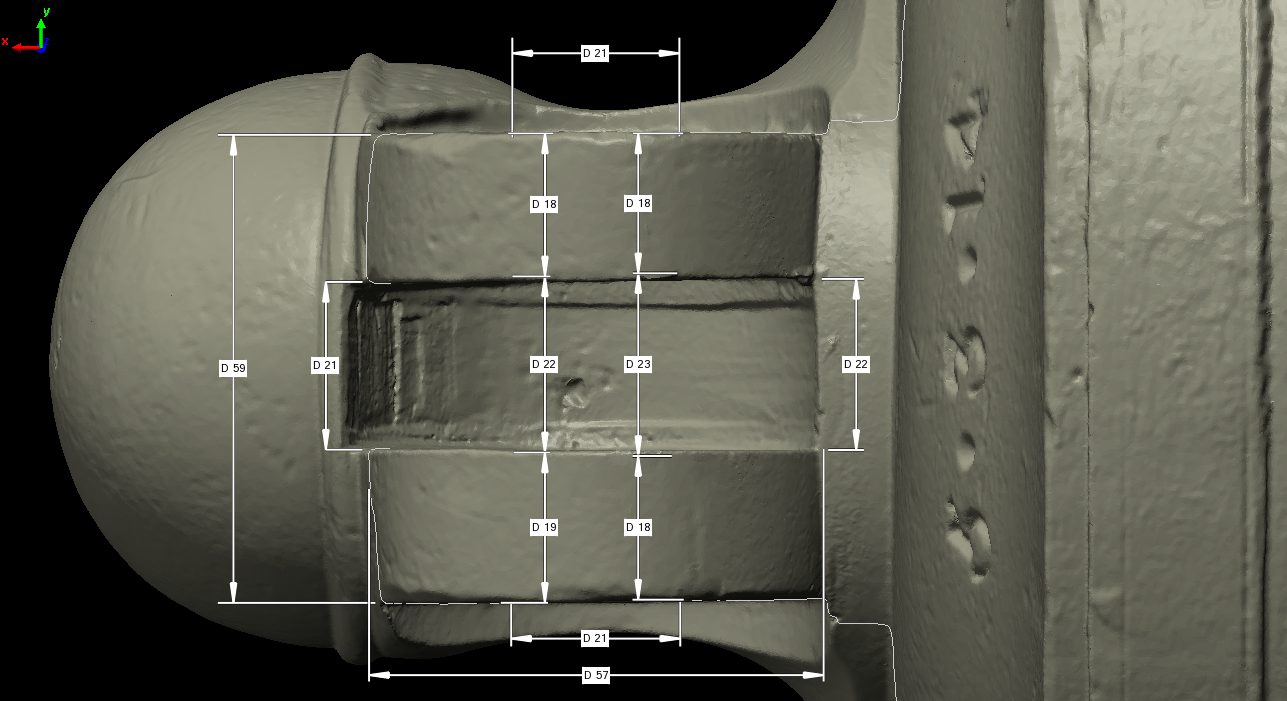

3D Scanners were asked to scan and produce a report on one of the eight identical bronze cannons. Archaeologists still often use hand drawing to record artefacts and David Knight wanted to explore the advantages of modern scanning techniques and demonstrate the advantages of this method using inspection software to create a visual report.

History

The cannons date from 1807. This was a period when England and France were at war, there were battles at sea with the French navy and privateers of both nations were very active.

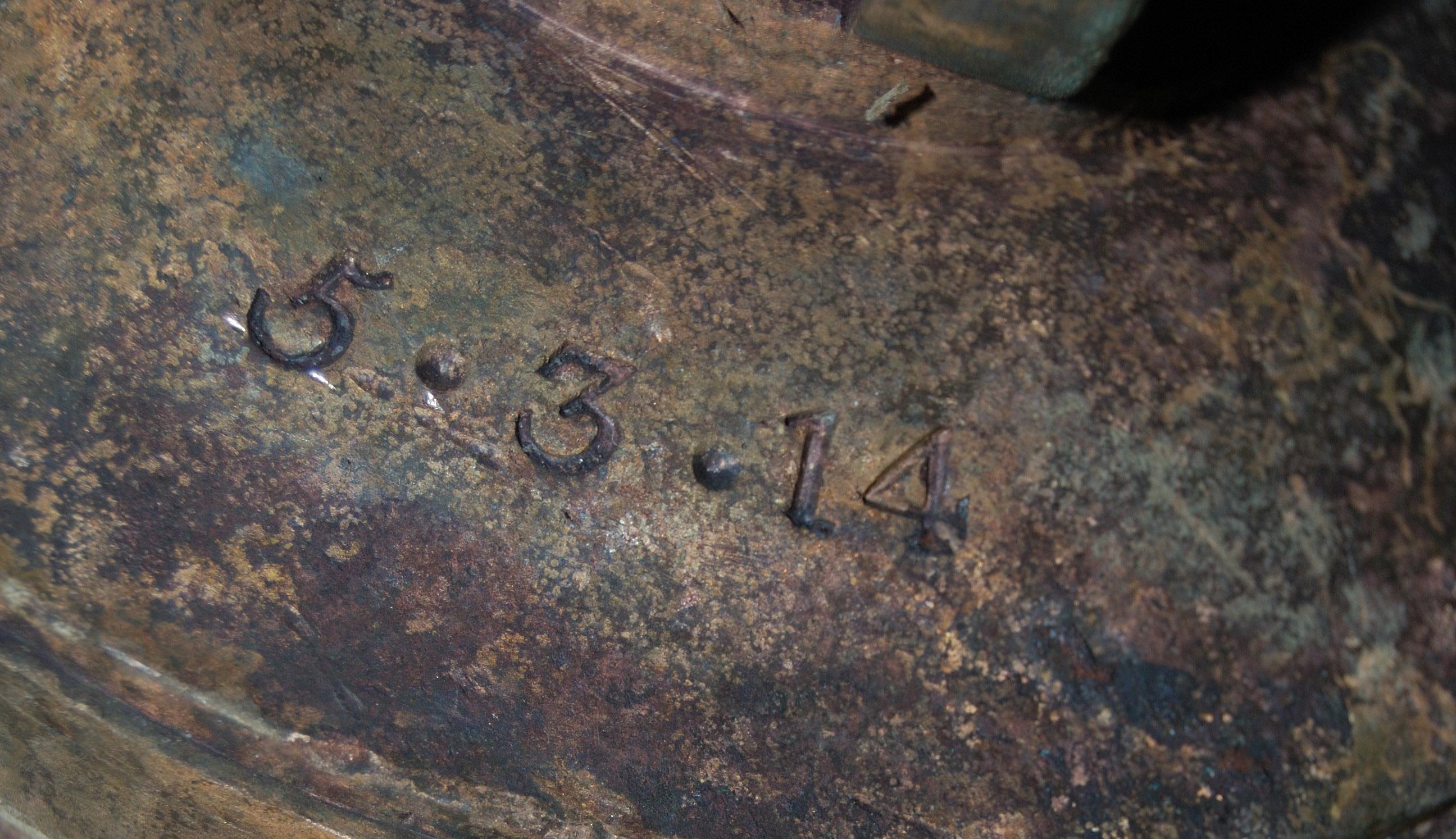

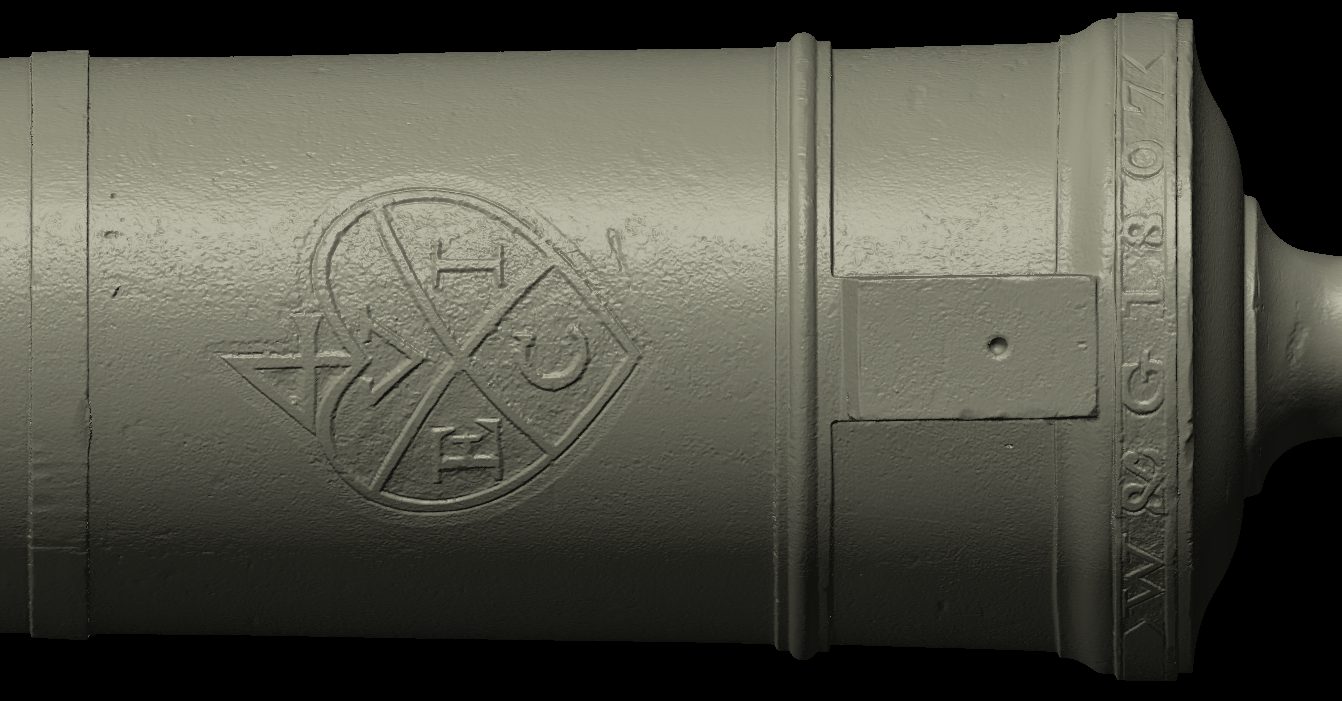

Following recovery, the cannons have been subject to conservation including the removal of encrustation and soaking over several years to reduce chloride levels and ensure their long term stability. The cannons are in exceptionally good condition for items recovered from the sea. They have a number of markings which will help with their identification. Cast into the surface at the base ring is the name William & Graham and the date. This company had a warehouse in the city of London and provided guns for ships and merchant companies to defend themselves from attack.

Also cast in, is the heart shaped mark of the United East India Company which was written as VEIC. This merchant mark was used by the company throughout the world on things like seals to goods, guns and small arms. While the company operated in many areas it’s main concern became governing India where it had its own army and ran the administration of the country.

The use of three dimensional scanning to record archaeological artefacts is still a relatively new and rarely used technique. It oers the advantages of greater accuracy when measuring the object and also allows a 3d model to be produced which can be viewed with the IMViewer by anyone at any point, with the advantage of creating a ‘3D library’. It also overcomes the problem of having to master computer drafting or the results being relatively simplistic hand drawn representations. It is likely that the use of 3D scanning will become more widespread.

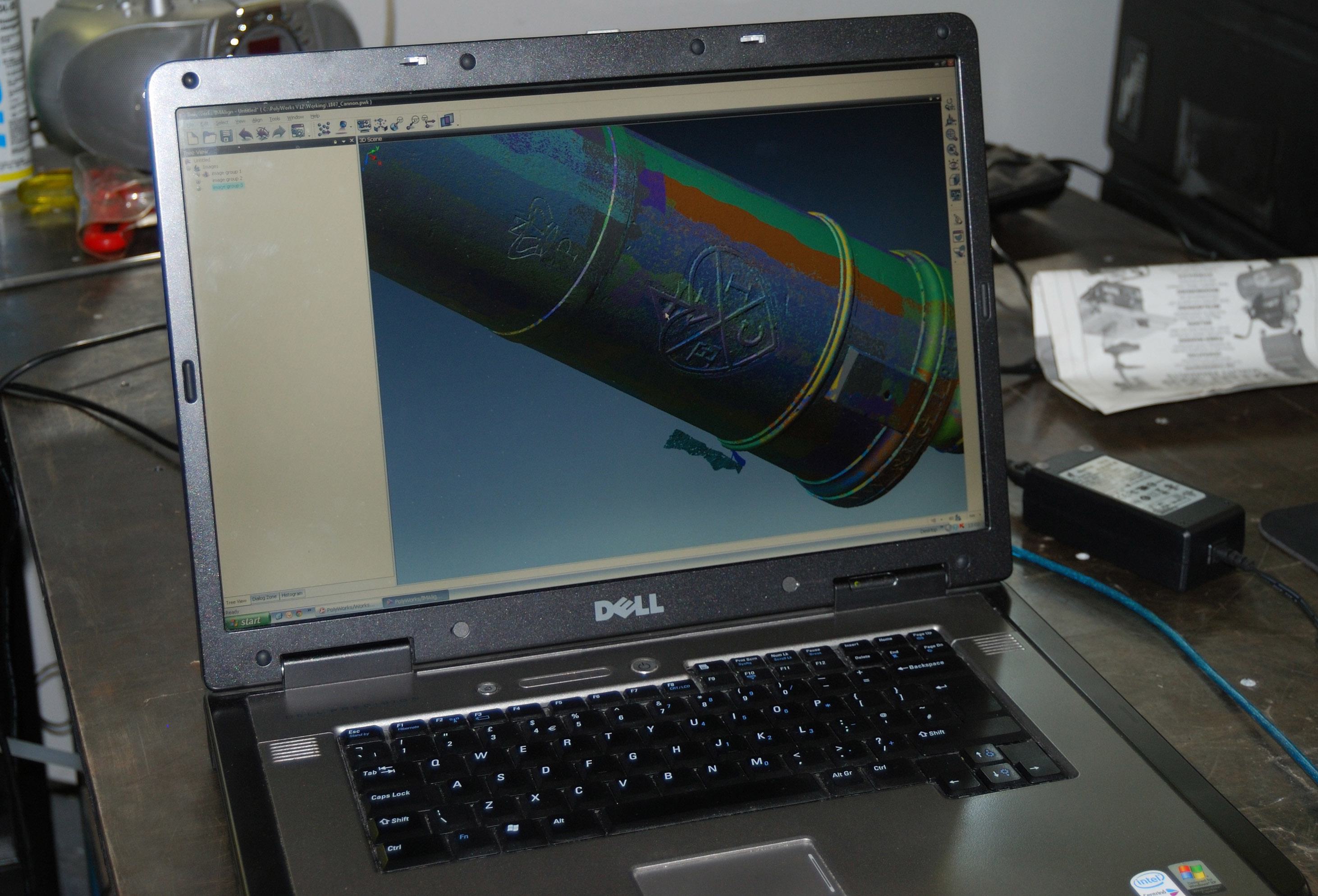

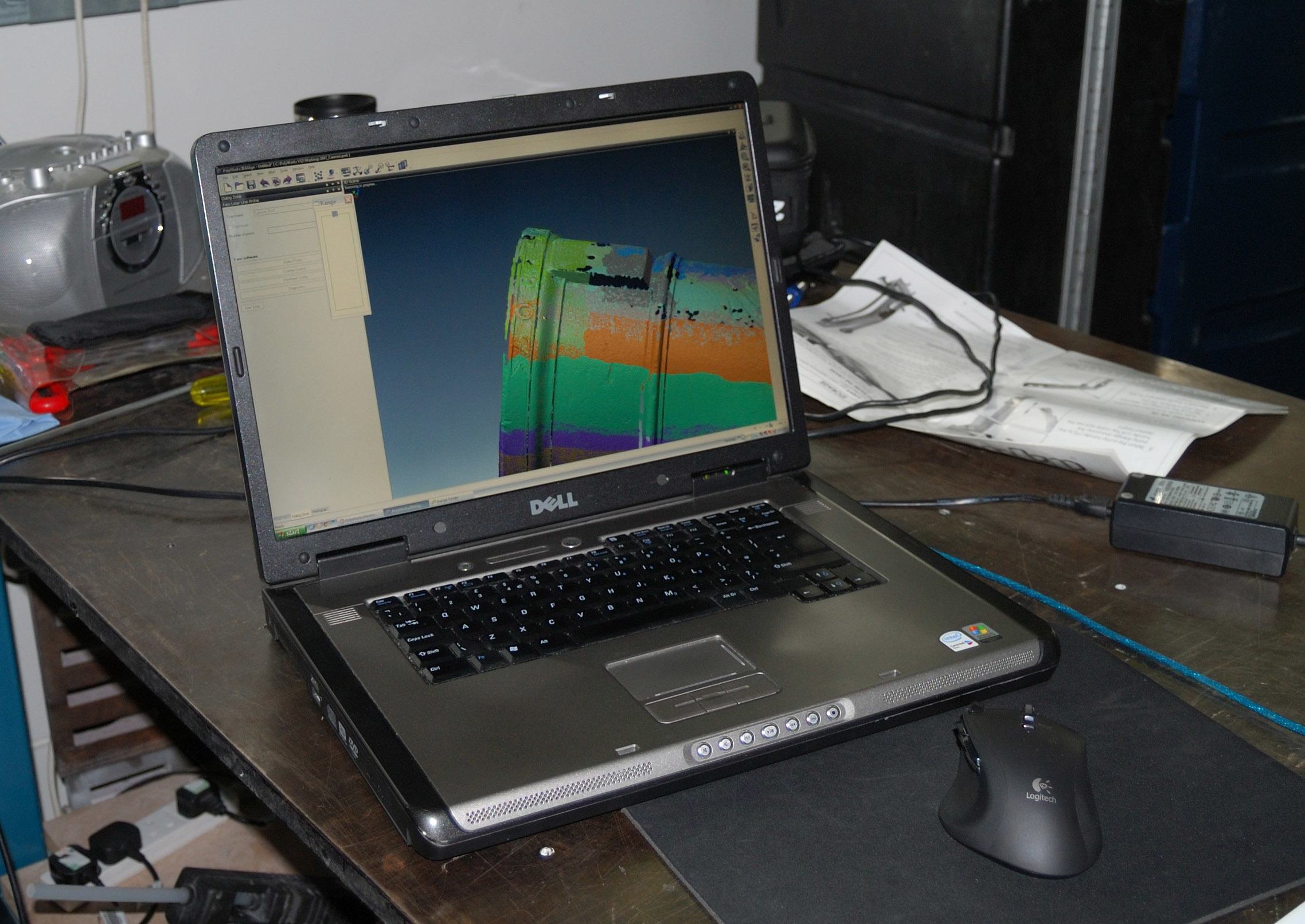

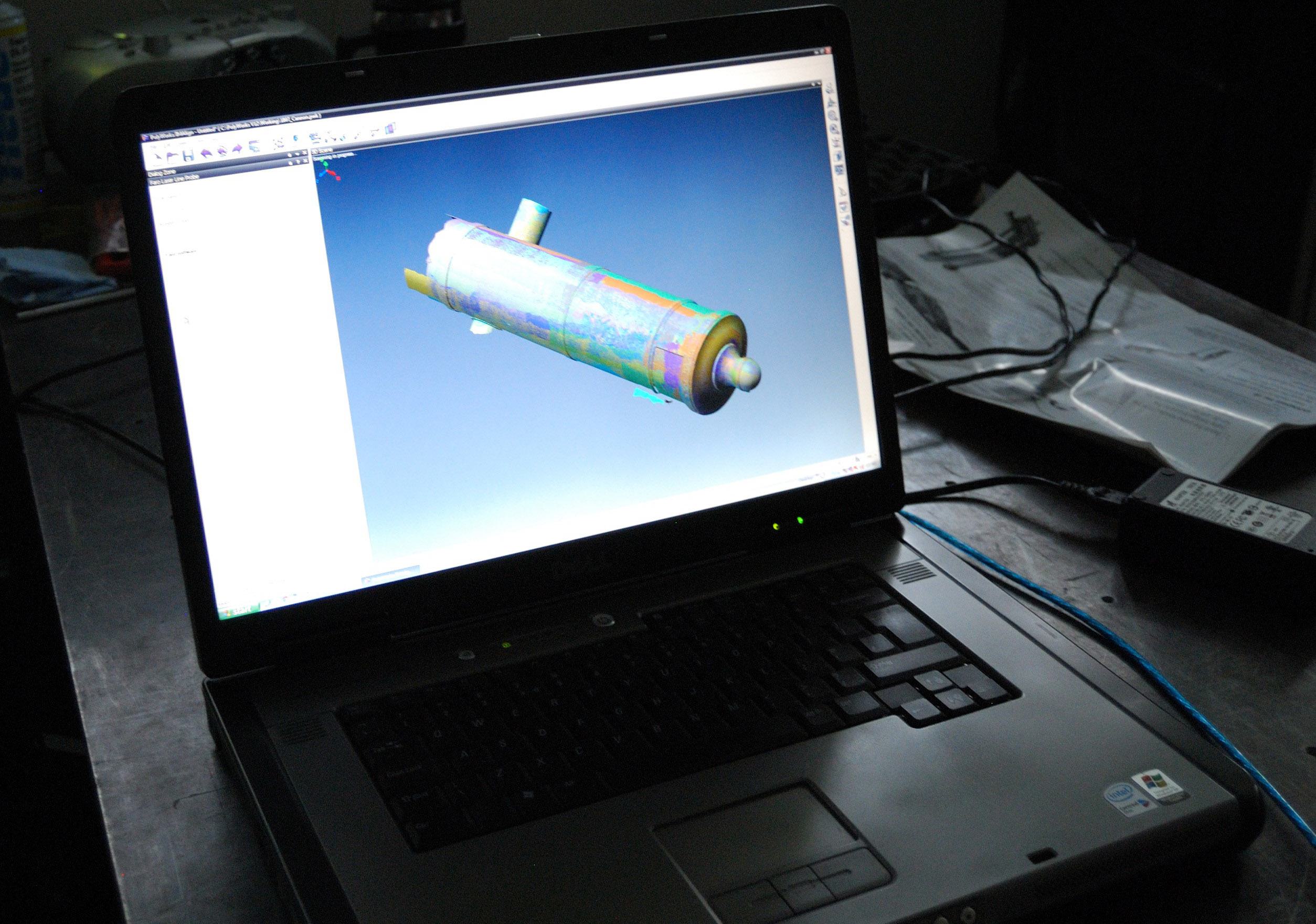

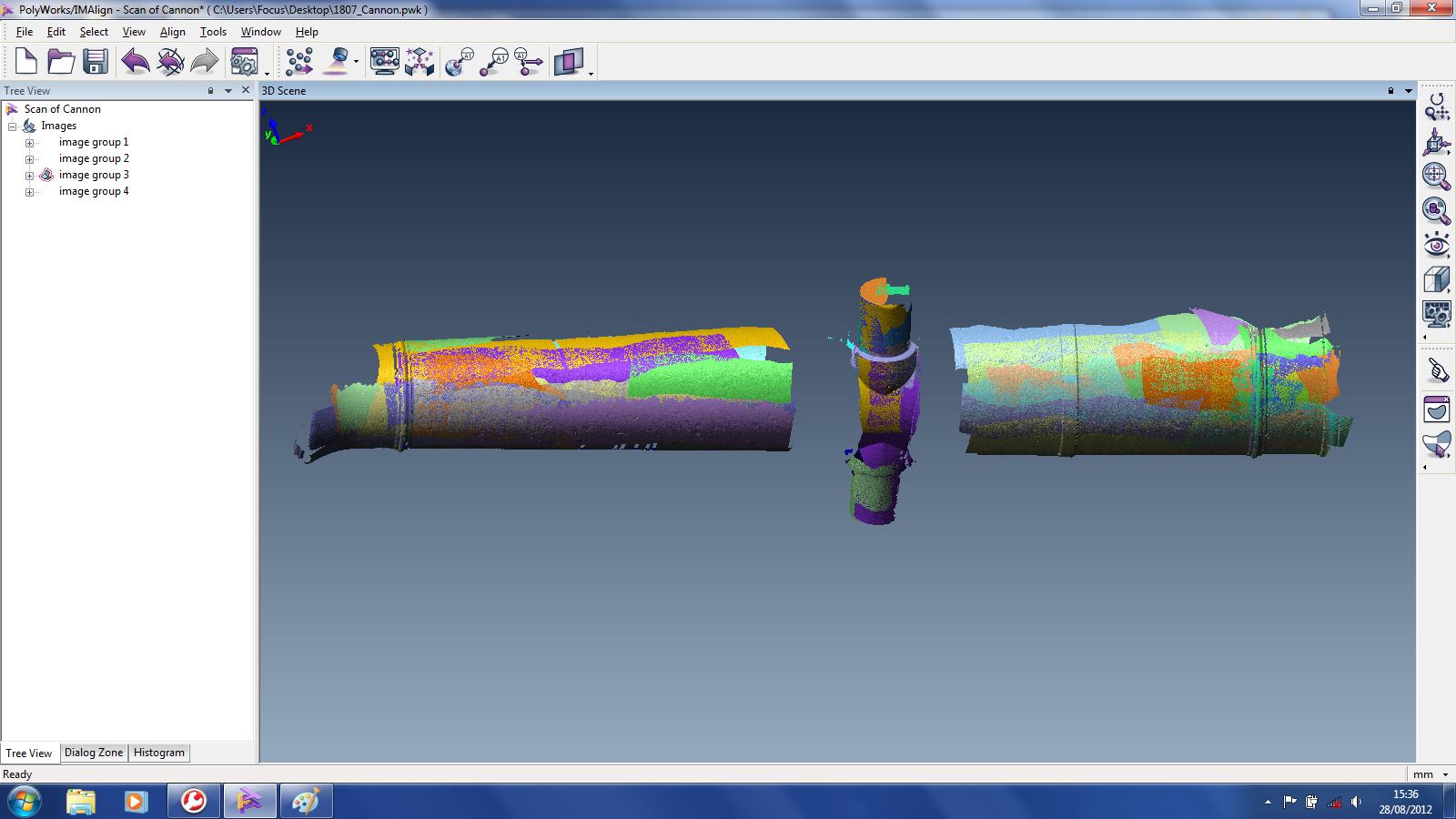

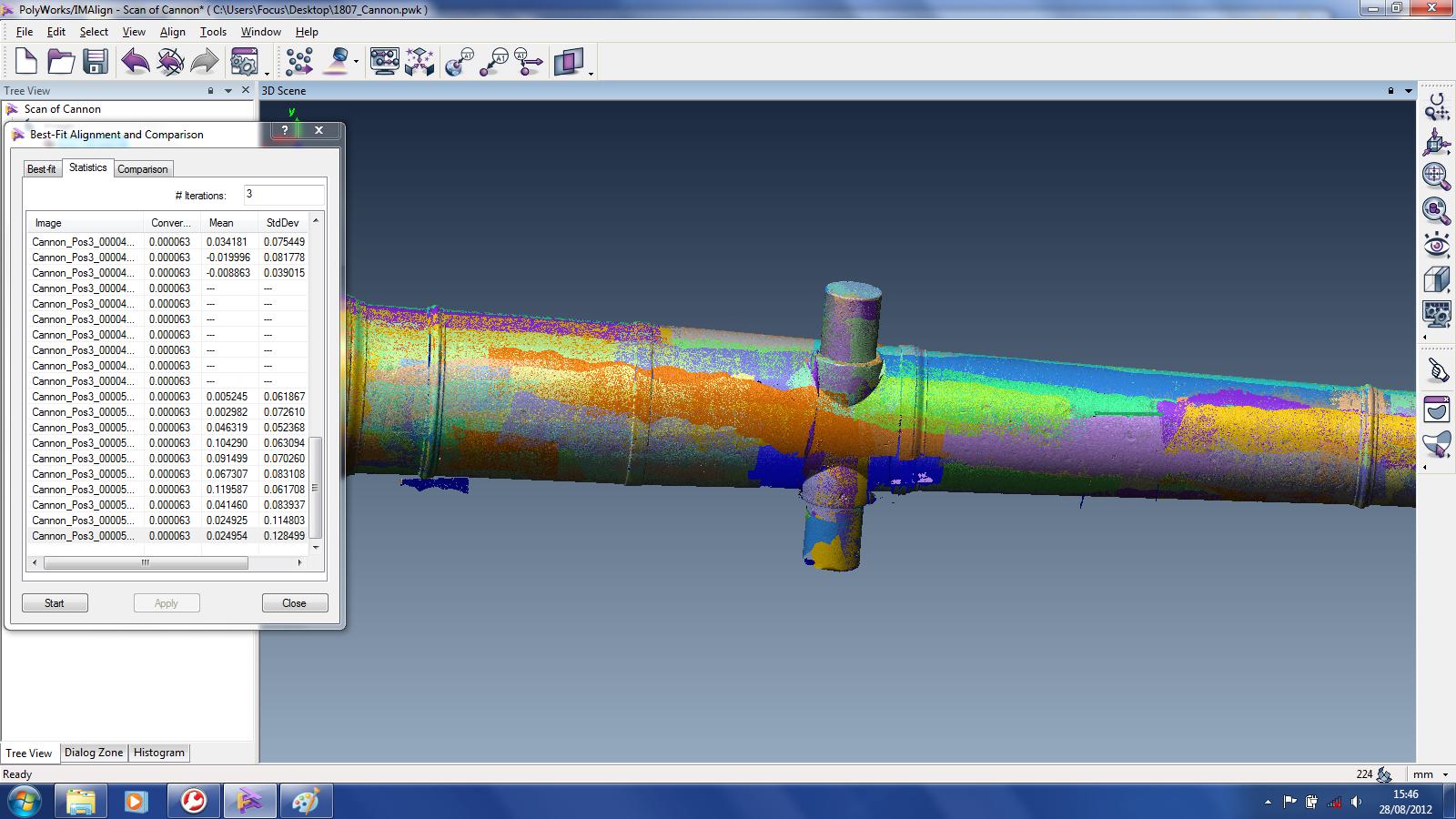

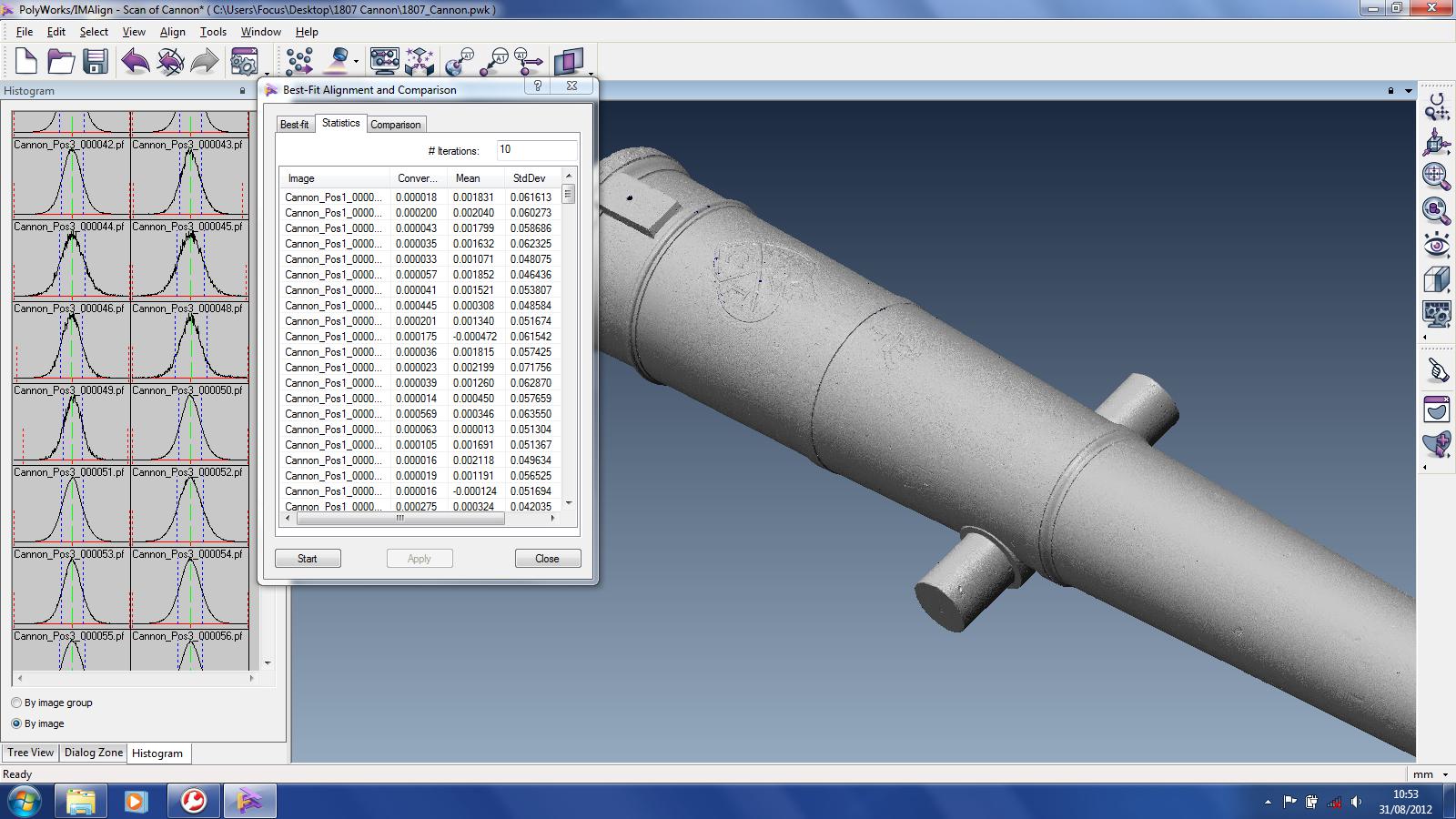

3D Scanners proceeded to scan the canon at their site in Coventry. It took half a day to scan the cannon using a 3d laser arm scanner. Particular attention was paid to the enscriptions, so that 3D Scanners achieved the best detail possible for the archaeologist report. The cannon also had to be lifted with a crane to allow them to achieve a full 360 degree scan. Due to the straps required to suspend the cannon on the crane, a few separate scans were needed to ensure full coverage. These would be best-fit aligned to approximately 50 microns during processing.

Once the cannon had been scanned, the data was processed in the 3D Scanners offices using PolyWorks software.

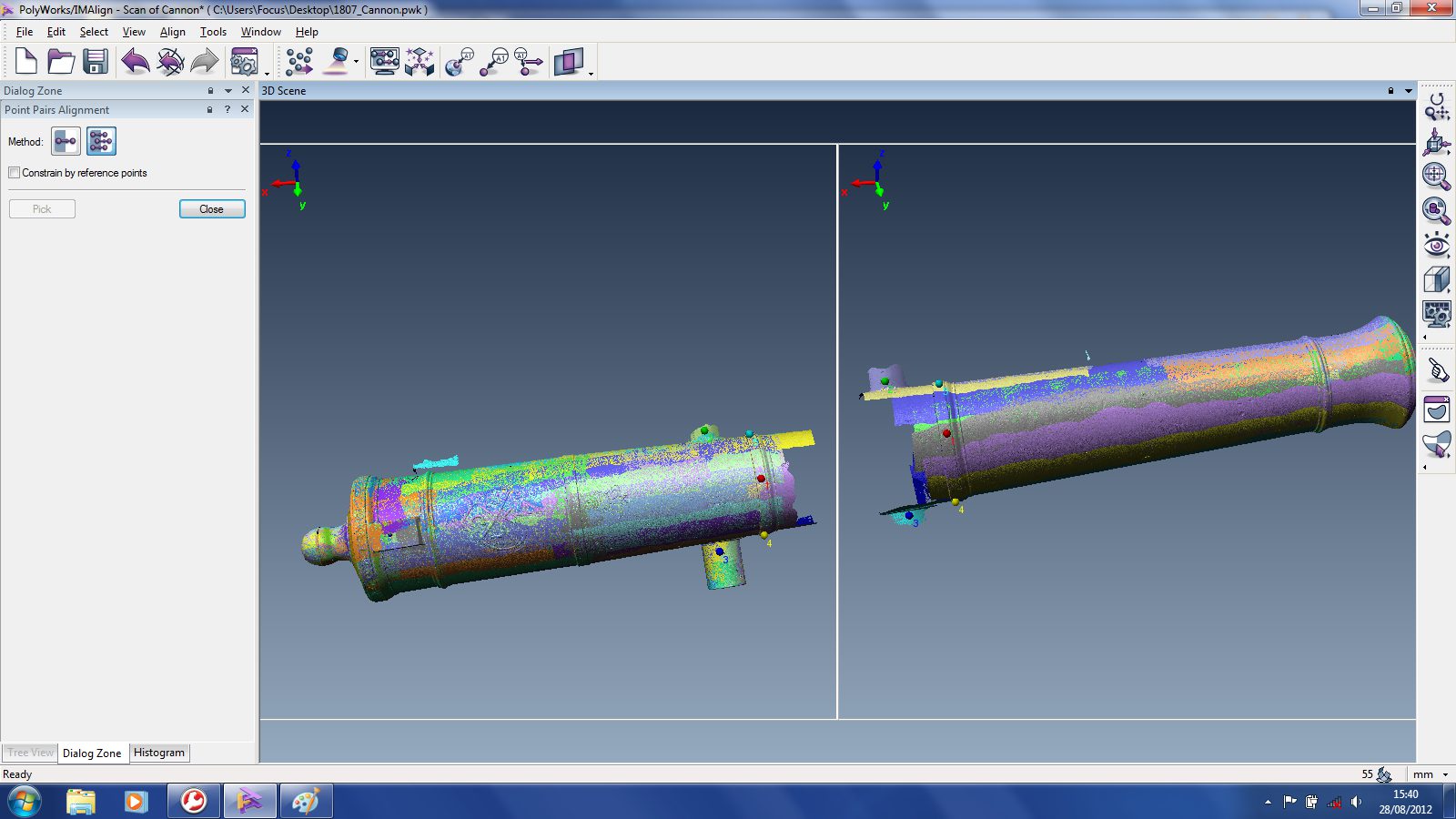

Alignment

The initial process was to align the pointclouds of each scan together, and then do a global alignment to bring the different sections together.

The customer was then given a pdf report as well as the workspace, and PolyWorks Viewer, which he could load on to his pc. This would allow him to view and rotate the cannon as a polygon mesh, create cross sections, and also create point to point measurements as well as viewing the dimensions within the workspace that 3D Scanners had already completed for the report.