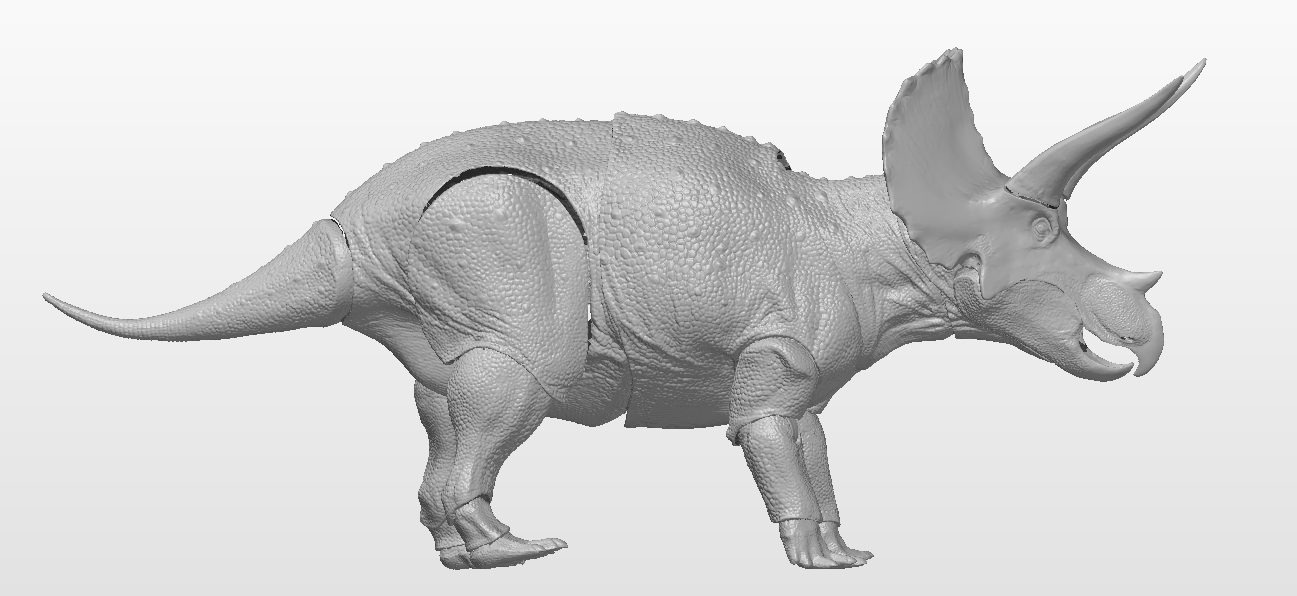

Our team was entrusted with the exciting challenge of creating a 3D digital model of a Dino-Riders toy, ensuring that any future accessories would fit seamlessly based on the precise measurements of our model. In order to capture every intricate detail of the toy, we employed advanced technology and hardware to conduct a thorough inspection of the part.

To achieve exceptional results, we utilised PolyWorks Inspector alongside a state-of-the-art 3d scanning arm. To facilitate easy access to every surface of the toy, we meticulously positioned it on a fixture that could be rotated without disrupting its joints.

Real-time quality meshing and point cloud from mesh were utilised to scan the part, ensuring excellent data coverage. To prevent any misalignment, we flipped the part over, again ensuring no movement on any of its joints.

After completing scans in the second part orientation, the two datasets were best fit together and stitched into a final polygonal model. The mesh was then refined using PolyWorks Modeler by filling gaps and smoothing out any residual noise, and the size was reduced to make the file manageable for the customer.