Industry 4.0 encompasses the integration of digital technologies, automation, data exchange, and advanced analytics. These new improvements help connect the real world with the ever-changing digital world.

Among the domains significantly influenced by Industry 4.0 is metrology, the science of measurement. Thanks to the leaps in technology, the metrology industry has been able to reach heights of accuracy and quality assurance that were previously unimaginable. In this blog we will discuss the impact of Industry 4.0 on metrology and the influences involved.

Internet of Things (IoT)

The Internet of Things refers to the network of interconnected devices and systems that can communicate and share data with each other over the internet. In the context of metrology, IoT devices are sensors and measurement instruments embedded in manufacturing equipment, machinery, and even products themselves. These devices can provide live data throughout the production process to make engineers aware of deviations, anomalies, quality issues, and other relevant information.

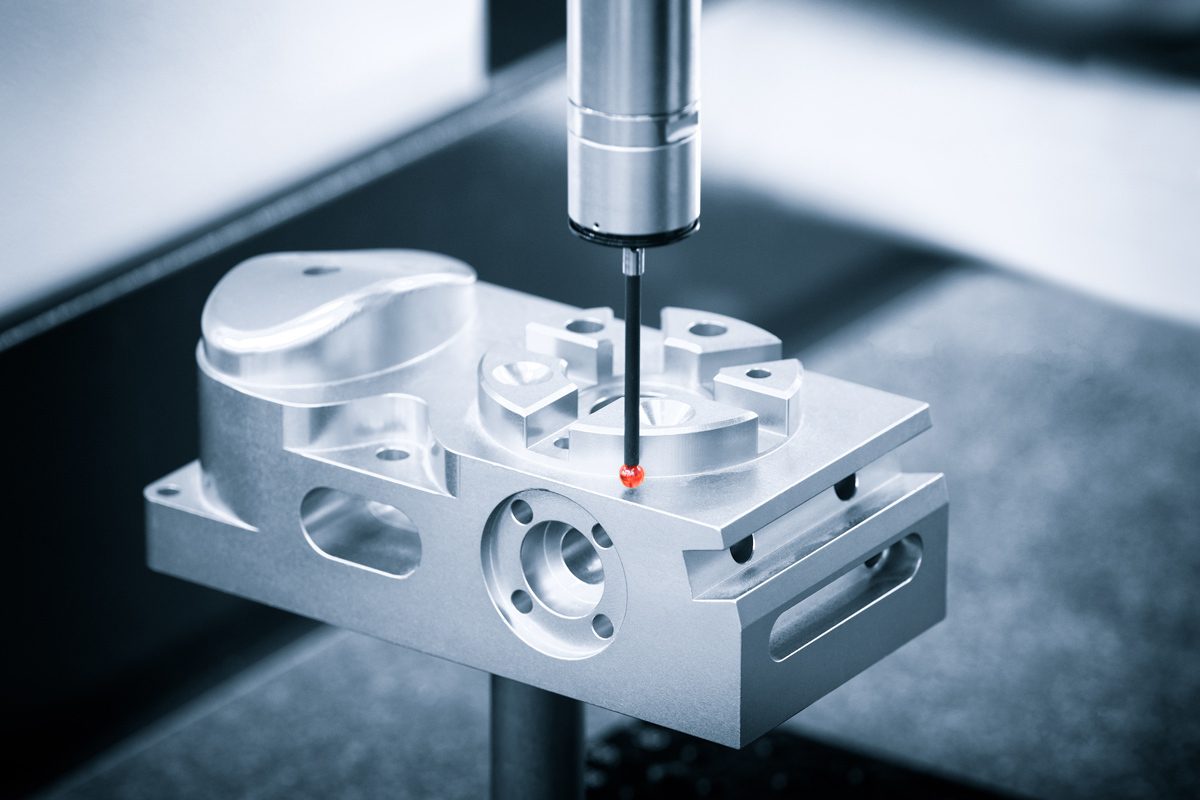

Advanced Sensors

Industry 4.0 has led to the development and deployment of highly advanced sensors that can capture data with remarkable precision and detail. They enable real-time measurements and monitoring, non-contact measurements, and multidimensional assessments, while their integration into automated systems streamlines processes and boosts efficiency. Unlike traditional sensors, they can capture data across multiple dimensions simultaneously which provides a better understanding of the object being measured.

Cloud Computing

Cloud computing provides a scalable and flexible infrastructure for storing, processing, and analysing the vast amounts of data generated by IoT devices and advanced sensors. Imagine cloud-based solutions as teamwork boosters. They let different groups, no matter where they are in the world work together and easily swap data.

Traditionally, companies would need an extensive on-site storage infrastructure to store their data, but now engineers can now upload the measurement data to the cloud which eliminates the need for this.

Data Analytics & Machine Learning

In metrology, data analytics plays a crucial role in making sense of the vast amounts of measurement data collected from various sources. Machine learning algorithms can be trained to analyse this data to recognise patterns or oddities within measurement data that might be difficult to spot through manual inspection alone. This helps engineers make smarter choices to improve the reliability of the measurements.

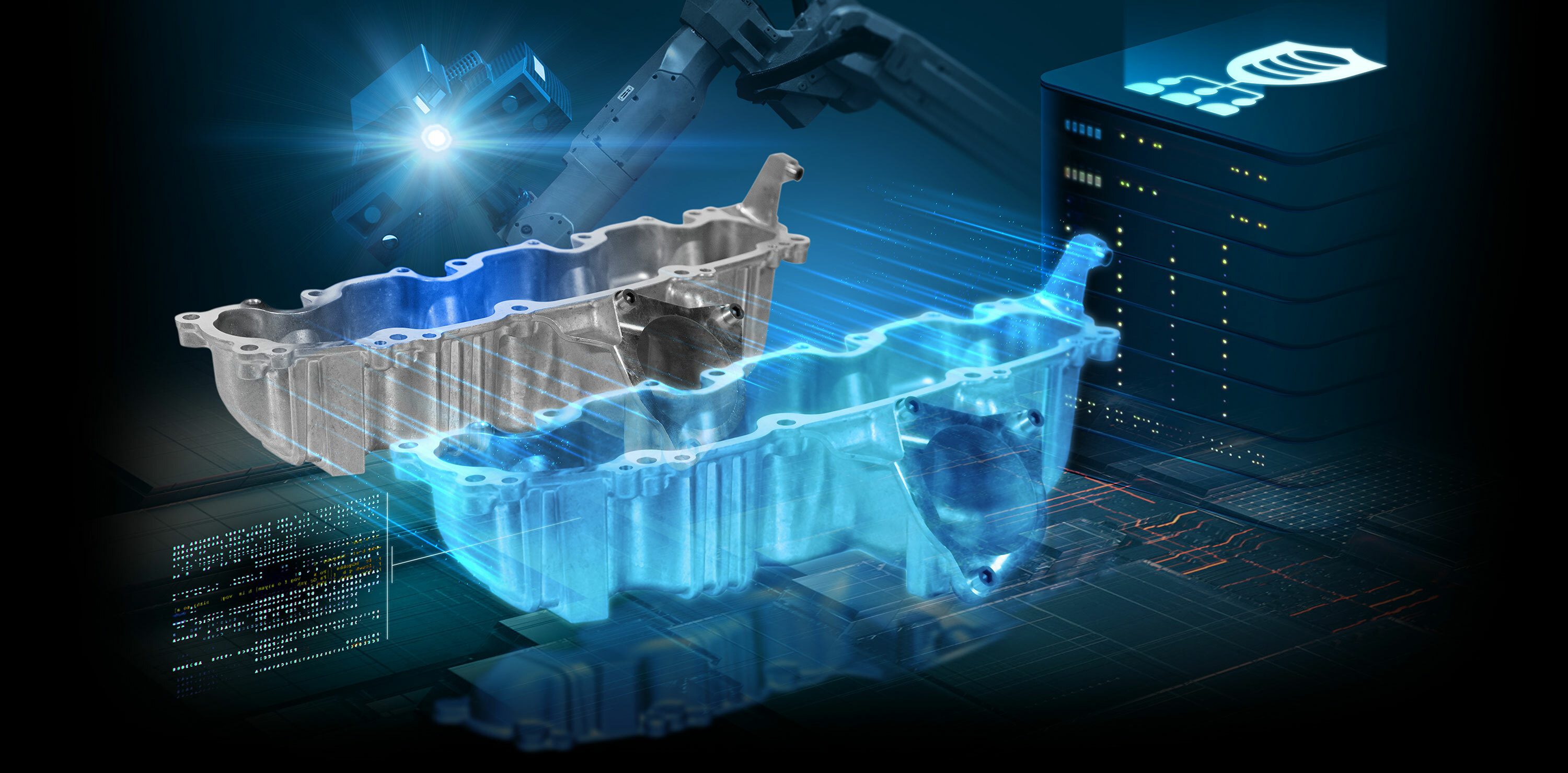

Digital Twins

A huge part of Industry 4.0 is the of connecting of the real world with the digital world. A digital twin is a virtual copy of a part or system that you can measure, test, and even simulate how it would react in different situations. It's like having a clone that you can experiment with without actually touching the real thing. By connecting physical parts from the real world with the virtual world, digital twins are making manufacturing smarter and more efficient.

PolyWorks DataLoop: The next-generation data management solution

PolyWorks Data Loop aligns with the Industry 4.0 framework by enabling the collection, integration, analysis, and utilisation of real-time measurement data to drive decision making. It contributes to the interconnected and technologically advanced manufacturing environment that Industry 4.0 aims to establish.

DataLoop enables enterprise-wide sharing of 3D measurement data and results, providing a digital collaboration platform that interconnects teams who capture and use 3D measurement information. As a scalable data management solution, it allows you to optimally handle large amounts of data produced by your 3D measurement activities by storing your inspection projects, their revisions and 3D measurement data in a centralised database.

The Future of Metrology

In the evolving landscape of Industry 4.0, metrology's importance grows. As measurement data seamlessly merges with the digital world, manufacturers are starting to see an increase in efficiency. It lays the foundation for manufacturing practices that are not just streamlined but are responsive to real-time insights and adaptable to dynamic market demands.