In today's advanced manufacturing and engineering industries, precision is extremely important. From ensuring the accurate measurements of components to maintaining tight tolerances, high precision metrology has a vital role. In this blog, we will explore the world of high precision metrology, discussing the concepts of precision and accuracy, understanding resolution in 3D scanning, exploring various types of metrology services, and highlighting the factors to consider for your specific application.

The difference between precision and accuracy in metrology:

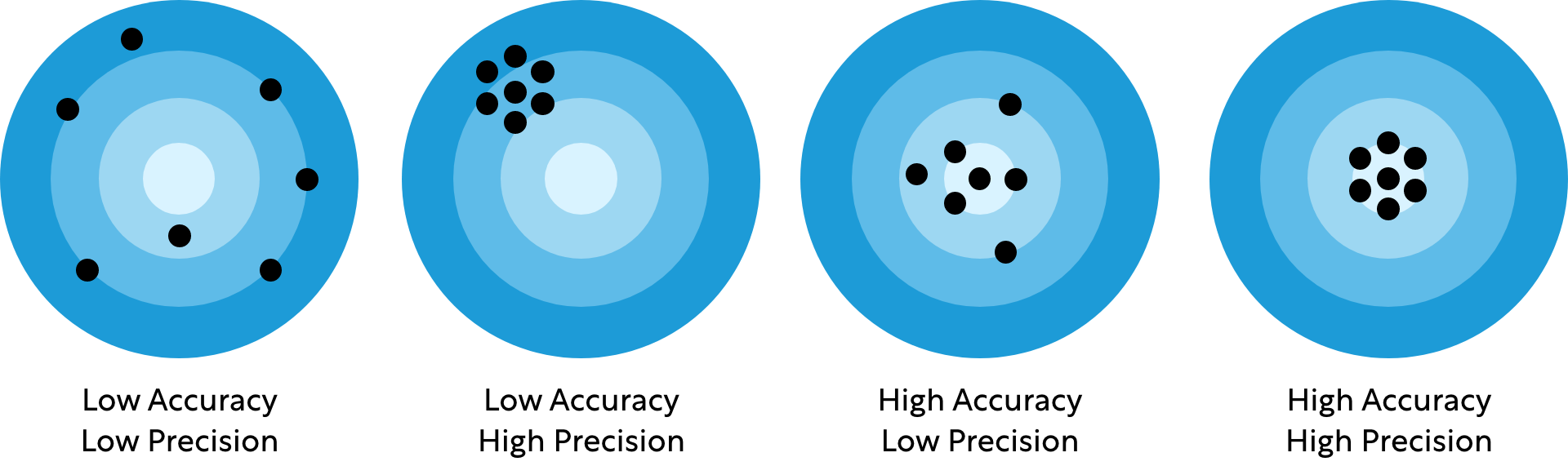

Precision refers to the degree of repeatability and consistency in measurements. Whereas accuracy refers to the degree of closeness between a measured value and the true value.

Precise but not accurate:

Measurement technology with good precision would show the same results no matter how many times you repeat it. But this doesn't mean it's accurate, as the readings could be offset by a certain value.

Accurate but not precise:

Measurement technology with good accuracy might be able to take readings that are close to the true value, but if it's not precise, then it will have low reproducibility and show different values every time you scan it.

Accurate and precise:

Measurement technology with high precision and accuracy will show results that can be repeated and are close to the true value.

The below graphic provides an easy way to visualise it.

What does "resolution" mean in 3D Scanning?

Resolution is the level of detail that can be provided from a 3D scanner. In the context of metrology, resolution relates to the smallest increment or feature that the scanner can accurately detect.

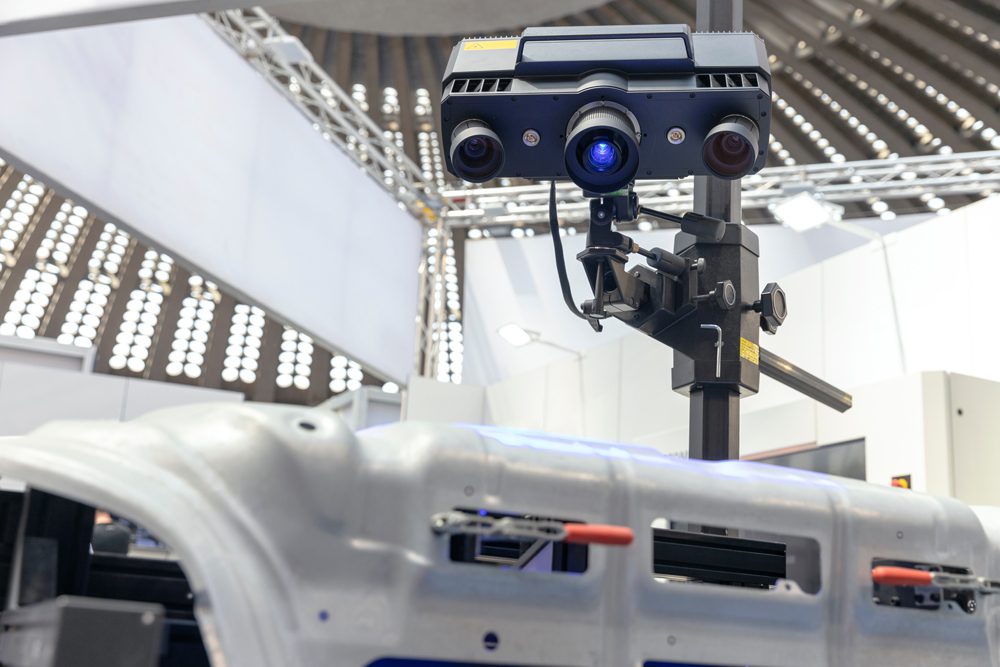

A high-resolution 3D scanner can capture intricate details and fine surface textures with greater precision. This level of detail is very important when it comes to reverse engineering and part inspection. By utilising advanced scanning technologies, such as structured light scanning or laser scanning, metrology service providers can offer precise and accurate 3D scanning solutions.

What are the various types of precision metrology services?

Precision metrology services encompass a wide range of techniques and technologies to ensure accurate measurements. 3D Scanners UK provide the following metrology services:

3D Scanning:

3D scanning is a rapid and precise method for digitally capturing the dimensions and form of a physical object. By gathering millions of points in space, a 3D scanning system generates a 3D point cloud. We offer a variety of non-contact scanning services customised to suit the unique requirements of your project. Our engineers will help you to choose the most economical solution that aligns with the level of precision needed.

Read more about our 3D scanning service

Reverse engineering and CAD modelling:

Reverse engineering involves recreating an object by thoroughly examining its structure or composition. Through the acquisition of scan data from the physical object, we generate a reliable CAD format capable of re-engineering the original item. If you don't possess the scan data, our 3D scanning service can gather the essential data, enabling us to proceed with the project and provide the desired CAD output.

Read more about our reverse engineering service

Part Inspection:

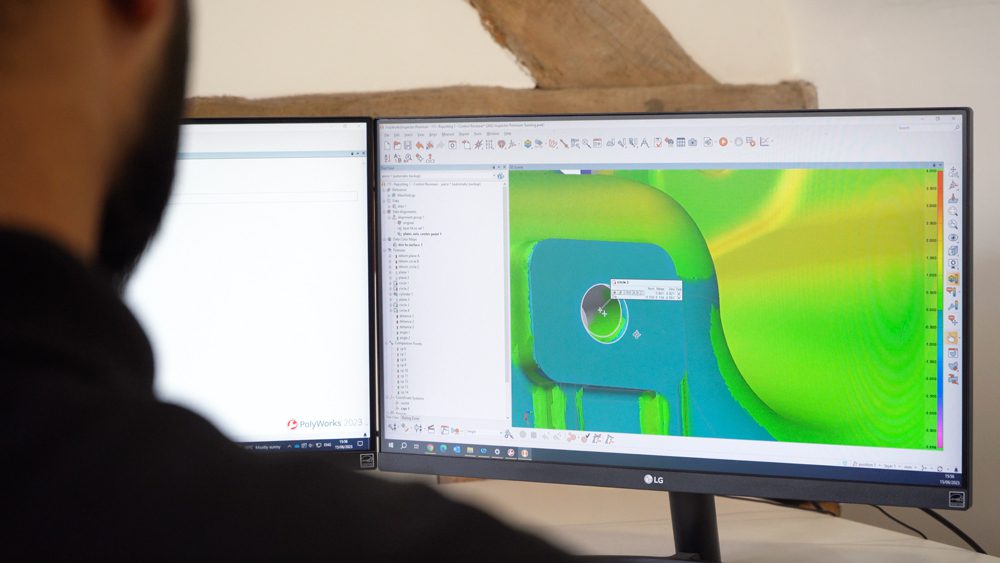

Part inspection compares the measured values obtained from a measurement device with reference materials like 3D CAD models or 2D drawings to assess the acceptability of a part. We provide a part inspection service that calculates the variance in your components. The inspection reports we generate are customised to meet your specific requirements, delivering essential information that enhances quality, reduces project timelines, and minimises costs.

Read more about our part inspection service

Factors to consider for your project:

If you're looking for a high precision metrology service provider, several factors should be considered:

Expertise and Experience:

A metrology provider with experience in your industry will have a deep understanding of your specific needs and will be better equipped to offer tailored solutions and handle the intricacies of your project.

Calibration and Traceability:

Ensure that the service provider follows rigorous calibration procedures and has traceability to recognised standards. Calibration is essential to establish the accuracy of measuring instruments, and traceability ensures that measurements are referenced to internationally accepted standards.

Quality Control Processes:

Inquire about the provider's quality control processes and certifications. A reliable provider should have robust quality control measures in place to ensure accurate and precise measurements. Look for certifications like ISO 9001, which demonstrate a commitment to quality management systems.

Turnaround Time:

Consider the turnaround time required for your measurements. Depending on your application's urgency, choose a provider who can deliver results within your required timeframe. Balancing speed with accuracy is crucial, so discuss the provider's turnaround time capabilities beforehand.

Customisation and Flexibility:

Assess whether the metrology service provider can customise their services to meet your specific needs. Different applications may have unique measurement requirements, so a provider who can adapt and customise their approach will be better suited to your application.

Data Reporting and Analysis:

Evaluate the provider's data reporting and analysis capabilities. Clear and comprehensive reports with detailed analysis will help you understand the measurement results effectively. Ensure that the provider can present the data in a format that is useful for your application and decision-making process.

Customer Support and Communication:

Consider the level of customer support and communication provided by the metrology service provider. Open and transparent communication channels, responsive customer support, and a willingness to address your queries and concerns are essential for a productive working relationship.

By carefully considering these factors, you can select a high precision metrology service provider that meets your specific application requirements. Taking the time to choose the right provider will ensure accurate and precise measurements, contributing to the overall success of your project.