PolyWorks Inspector™ Tip

When scanning parts for inspection, your result probably contains unwanted scan data, such as fixturing, which can be time consuming to remove manually. This unwanted data can be easily removed, once the scan has been aligned to the corresponding CAD model, using a data point selection tool based on the surface of the CAD model. In this way, you can accelerate your scan data cleanup process, saving you valuable time!

Step by step: To clean the aligned scan of a part using the corresponding CAD model:

- Right-click the scanned Data object in the 3D Scene and choose Select > Elements > Using Reference Object Surfaces on the shortcut menu that displays. The Select Data Points using Surfaces dialog box opens, with the clicked Data object already specified in the Data objects list.

- In the dialog box, make the following specifications to select the desired scanned data:

- Set Direction to Shortest.

- Set Max distance to a value that is slightly greater than the largest expected deviation on the part.

- If there is more than one CAD model, set Reference objects to Specific and select the appropriate object in the list that is displayed.

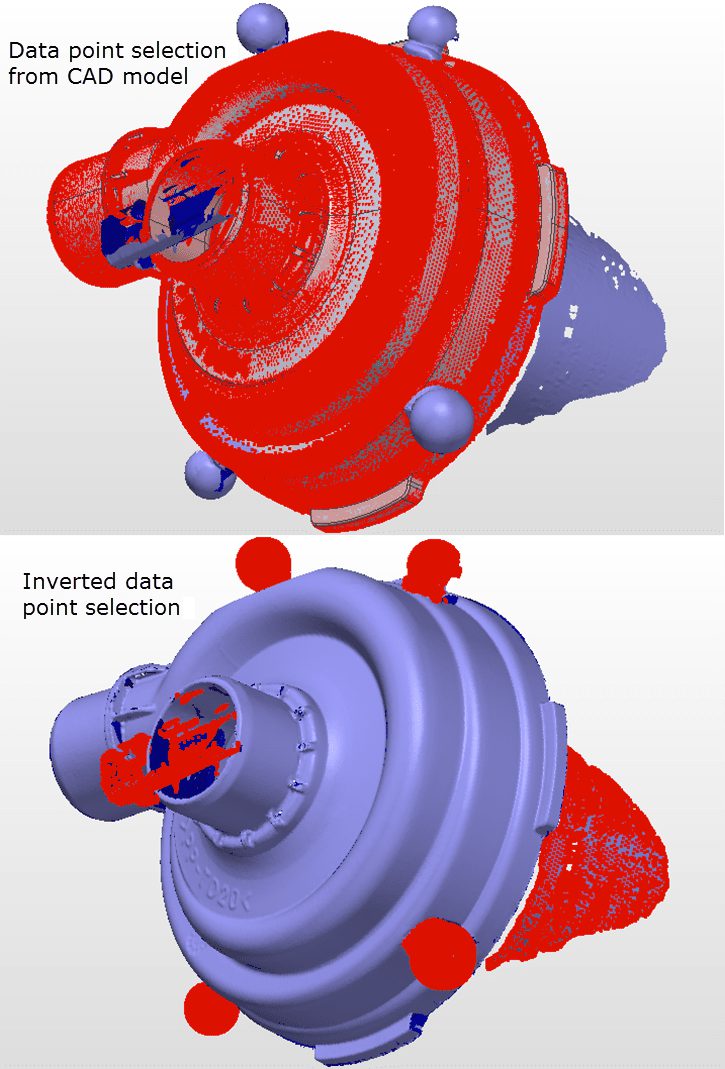

- Click Select and Close. The desired scanned data is selected and shown in red in the 3D Scene.

- Right-click the scanned Data object in the 3D Scene, then choose Select > Elements > Invert on the shortcut menu that displays. The unwanted scan data is selected and shown in red in the 3D Scene.

Make sure the highlighted data is what you want to delete, then press the DELETE key.